Alright, let’s talk about car manifolds. I remember scratching my head about these things way back. My buddy Dave’s old truck started sounding like a popcorn machine and lost some serious ‘get up and go’. So, naturally, we popped the hood to play detective.

First thing you see bolted right onto the engine block, usually on the sides or maybe top/bottom depending on the engine design, are these pipe-looking structures. Turns out, there are usually two main types, and they do pretty opposite jobs, which kinda makes sense when you think about it.

The Noisy One – Exhaust Manifold

So, with Dave’s truck, the racket was coming from this heavy, often rusty-looking cast iron thing. We traced the exhaust pipe back up to the engine, and it connected right to this manifold. It took me a bit, but I figured it out. Each little pipe on this manifold connects to one cylinder head port – that’s where the engine spits out the burnt gas after the little explosion inside.

Its whole job is basically collecting all that super hot, nasty exhaust gas from all the different cylinders and funneling it into one pipe – the start of your exhaust system. Think of it like a collector. On Dave’s truck, the gasket between this manifold and the engine head was shot, leaking exhaust and making all that noise. We wrestled the old one off, cleaned the surfaces, slapped a new gasket on there, and tightened it back down. Noise gone. Simple idea, really – get the bad stuff out and away.

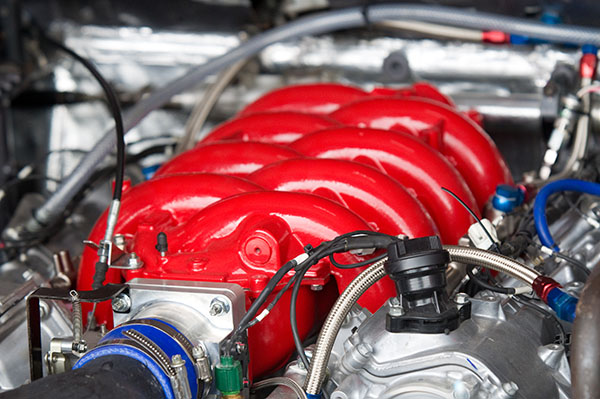

The Breathing One – Intake Manifold

Okay, so if the exhaust one gets stuff out, the other one must get stuff in, right? That’s the intake manifold. You’ll find this one connected to the part of the engine where air (and sometimes fuel) goes into the cylinders. It looks kinda similar, a bunch of pipes leading to each cylinder, but its job is distribution.

It takes the air coming from your air filter (and throttle body) and splits that airflow evenly, or as evenly as possible, sending it down separate runners or pipes into each cylinder head intake port. The engine needs air to mix with fuel to make power, and this manifold is the delivery system. It makes sure each cylinder gets its share of air to breathe.

Sometimes these are made of metal, sometimes plastic or composite stuff these days. If this one leaks (like a bad gasket or a crack), it can suck in extra air the engine isn’t expecting. That messes up the air-fuel mixture and can cause rough idling, stalling, and power loss – kinda like the sluggishness Dave was also complaining about. We checked for vacuum leaks around his intake manifold too, spraying some carb cleaner carefully around the gasket edges to see if the engine speed changed. Found a small leak there too!

So yeah, that’s the gist from my messing around. You got an exhaust manifold to collect the burnt gases and send ’em out the tailpipe, and an intake manifold to deliver fresh air (and sometimes fuel) into the engine so it can run. They’re like the engine’s lungs, in a way – one breathing in, the other breathing out. Nothing too fancy, just directing traffic for air and exhaust.