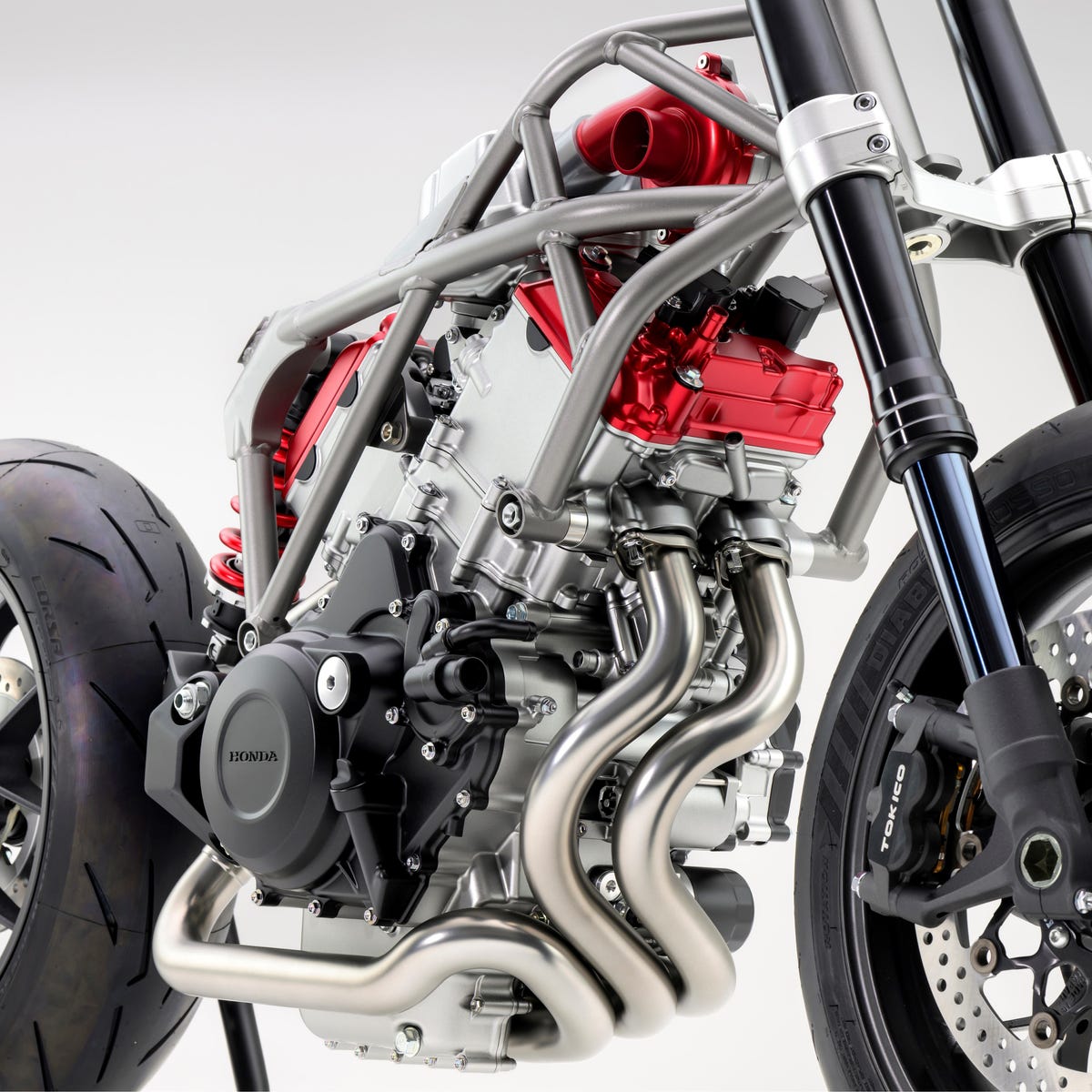

Alright, so today I’m gonna walk you through my little adventure with the Honda V3 project. Buckle up, it’s a bit of a ride!

It all started when I stumbled upon this old Honda engine. It was sitting in my garage, collecting dust, and I thought, “Hey, why not try something crazy?” I’d heard whispers about the V3 configuration – not super common, but intriguing. So, I decided to tear it down and see what I could do with it.

First things first, I grabbed my trusty tools – wrenches, sockets, the whole shebang – and started stripping the engine down. Let me tell you, it was a greasy mess! Took hours just to get everything clean enough to actually see what I was working with. I took a bunch of pictures during the disassembly, which later saved my bacon ’cause I totally forgot where some of the parts went, haha!

Once I had all the components laid out, I began inspecting them. The cylinders were in okay shape, but the pistons definitely needed some love. There was some scoring and carbon buildup, so I spent a good chunk of time cleaning them up and checking the tolerances. I measured everything like five times to make sure I wasn’t missing anything. Precision is key, ya know?

Next up was the crankshaft. This thing was a beast! I checked the bearings, and they seemed alright, but I decided to replace them anyway for peace of mind. Also, I gave the crankshaft a good polish ’cause, why not? A little bling never hurt anyone.

The cylinder head was where things got interesting. The valves were pretty gunked up, and the valve seats needed some serious attention. I lapped the valves until they were sealing perfectly. That took forever, I swear. My hands were killing me!

Now, here’s where I got a little ambitious. I decided to try my hand at porting and polishing the cylinder head. I’d watched a bunch of YouTube videos on it, so I figured I could give it a shot. I carefully removed some material from the intake and exhaust ports to improve airflow. I wasn’t trying to go crazy, just smoothing things out a bit.

Reassembly was the next challenge. I followed my disassembly photos religiously! I started with the crankshaft and pistons, making sure everything was properly lubricated. Then came the cylinder head, which was a bit tricky to get torqued down correctly. I double-checked the torque specs like a maniac.

With the engine mostly back together, I moved on to the carburetors. These things were a nightmare! They were completely clogged with old fuel. I spent hours cleaning them, replacing jets, and making sure everything was synchronized. Carbs are definitely not my favorite part of engine work.

Finally, the moment of truth! I bolted the engine back into the frame, hooked up the fuel and electrical connections, and crossed my fingers. I hit the starter button, and after a few cranks, it fired up! It sounded a little rough at first, but after some fine-tuning, it settled into a smooth idle. I was so stoked!

The V3 still needs some tweaking, but it’s running! It was a long and challenging project, but I learned a ton. And now I’ve got a cool, custom Honda V3 that I can cruise around on. Not bad for a pile of garage junk, eh?

So yeah, that’s my Honda V3 story. Hope you enjoyed it. Maybe it’ll inspire you to tackle your own crazy project. Just remember to take pictures, be patient, and don’t be afraid to ask for help. Happy wrenching!