So, this “Seattle Slew Drive” project, yeah, it landed right on my bench. Don’t even ask why they called it that. Maybe ’cause it was supposed to be a real champion performer, or maybe ’cause it was just plain stubborn before you got it moving. Who really gets these project names anyway?

First thing I noticed? Nobody really had a clear picture of how this darn thing was supposed to fit into the bigger assembly. We had the slew drive unit, a hefty chunk of metal, and a mess of wires. And the manual? Looked like someone fed it through a shredder and then tried to tape it back together after a bad translation job. Pretty much useless, to be honest.

Here’s what I first tried, my grand strategy, you know:

- Spending what felt like ages meticulously tracing every single wire. Super exciting stuff.

- Then, trying to make sense of the motor specs against the controller unit we had on hand. Big surprise: they weren’t exactly best friends.

- Actually going and talking to the folks who ordered the drive. Turns out, their selection process was basically “this one looked about right in the catalog.” Real helpful, that was.

So there I was, day in and day out, just battling to get this thing to spin. The controller kept throwing errors. The motor would make these awful groaning noises, jerk a tiny bit, and then just give up. Honestly, it felt like I was trying to coax a performance out of a pet rock.

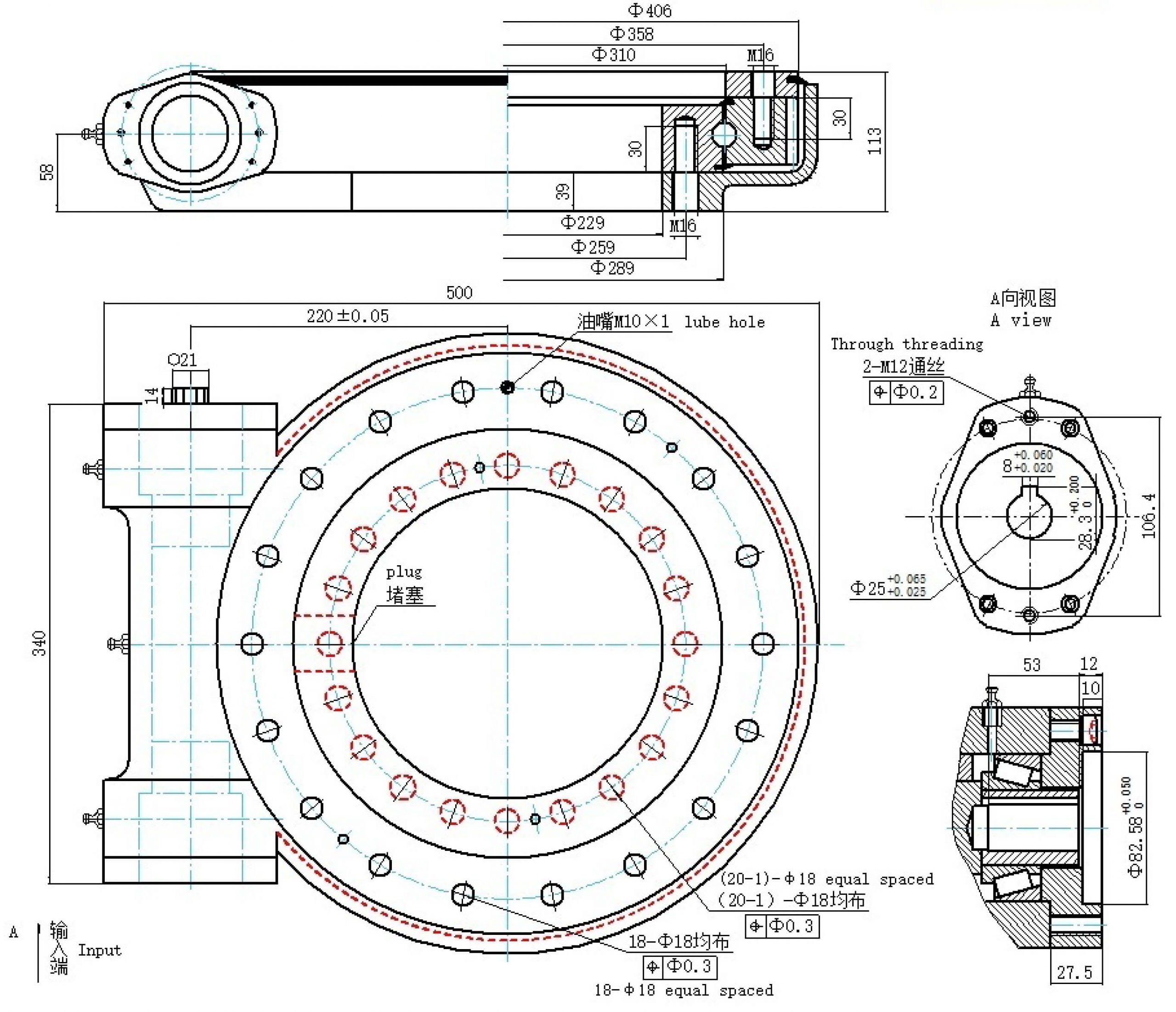

And don’t even get me started on the mounting. Oh, the sheer joy of the mounting. The bolt pattern was just off enough from standard to be a complete pain. Which, naturally, meant it wasn’t standard at all. I had to sweet-talk the guys in the machine shop to drill new holes for me. That, of course, took an eternity because their main drill press was on the fritz. Just a typical day, right?

You’re probably wondering, why me? How did I end up being the one wrestling with this particular beast? That’s a fair question.

See, I sort of stumbled into this workshop role. I used to be a software guy – you know, comfy office chair, climate control, the whole package. Then came the big “corporate reshuffle.” And just like that, poof. My entire department went up in smoke. They dangled this spot in front of me, “hands-on engineering,” they called it. Pitched it as a “fantastic opportunity for career growth.” Translation: they needed someone, anyone, to throw at the messy problems nobody else wanted to touch.

Those first few weeks were something else. Pure, unadulterated chaos. I mean, I knew how to handle a soldering iron from messing around with electronics as a hobby, but this industrial-grade machinery? That was a whole different ball game. And of course, nobody really had the bandwidth to show me the ropes properly. It was pretty much learn as you go, or drown. So, I started paddling. Or, more accurately, flailing around hoping I’d eventually float.

Anyway, getting back to this Seattle Slew headache. After what felt like an eternity of banging my head against the wall, fueled by way too much coffee and probably a few too many muttered curses, I finally figured it out. It wasn’t one single, massive problem. Nope. It was a series of small, incredibly silly things all conspiring against me.

- There was this one parameter in the controller, hidden about five menus deep, that was completely wrong.

- A power supply connection that was just a tiny bit loose – enough to cause these random, untraceable faults.

- And the real kicker: the emergency stop button was wired completely backward. Normally open instead of normally closed. So, effectively, the system thought it was always in an emergency stop state. Brilliant.

Felt like I was solving a crime committed by an idiot. But, once I sorted those little gremlins out, guess what? Old Seattle Slew actually started to turn. And smoothly, too! Like it knew how to do it all along and was just having a laugh at my expense.

So yeah, that was my little adventure with the Seattle Slew Drive. Nothing too glamorous, mostly just me versus a stubborn piece of equipment. But hey, it spins now. And I suppose I learned a valuable lesson or two about not trusting shiny catalog pictures and always, always double-checking the emergency stop wiring. Every single time.