Okay, so, I’ve been messing around with this old 4-cylinder engine I had lying around, trying to see if I could squeeze some more power out of it. Figured I’d share my little adventure, maybe someone else will get a kick out of it.

Getting Started

First, I dusted off the engine, it was covered with a thick layer of oily grime. It’s one of those older ones that has been sitting in my garage for ages. I grabbed my tools and started tearing it down. It was pretty straightforward. Unbolted this, disconnected that, just your basic disassembly. The goal here was to see what I was working with and get a good look at the insides.

Cleaning and Inspecting

Once I had it all apart, I gave everything a good cleaning. Let me tell you, there was some serious gunk built up in there. I used a bunch of degreaser and scrubbed until my arms were sore. Then, I took a close look at each part. I checked for wear and tear, cracks, anything that looked off. The cylinder walls were pretty decent, but I still decided to give them a light hone, just to smooth things out a bit.

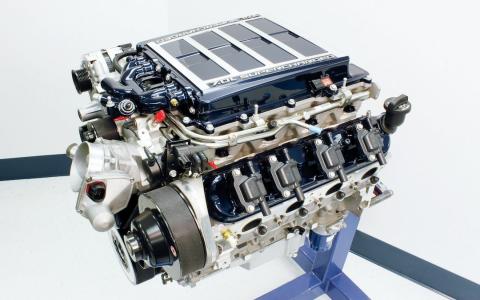

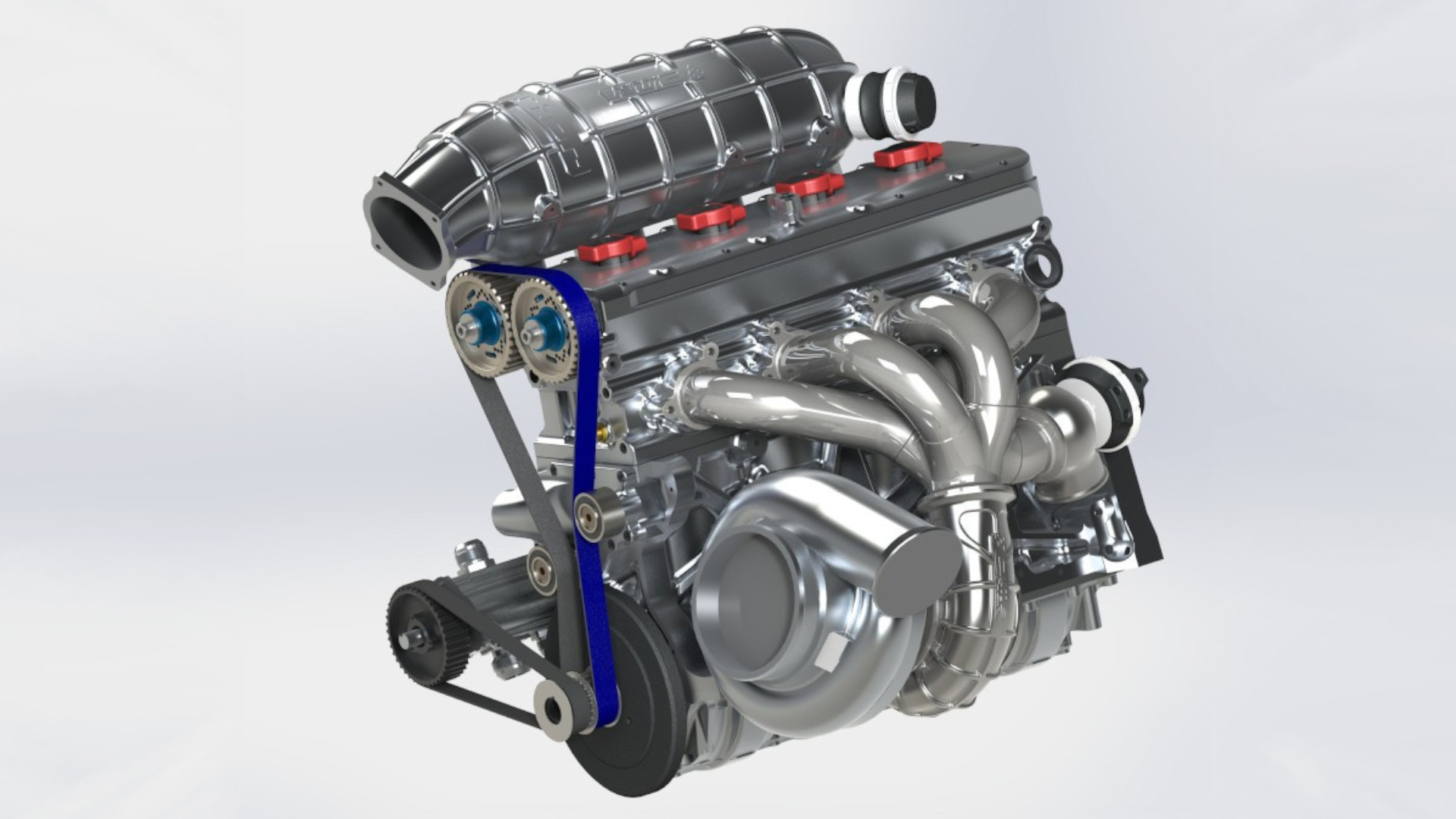

The Supercharger

Now for the fun part, the supercharger. I snagged a used one online. It wasn’t exactly meant for this engine, but I figured I could make it work. This involved some, shall we say, “creative” engineering. I had to fabricate a custom bracket to mount it. It took me a couple of days of welding, drilling and then some more welding because I messed it up, but I finally got it bolted on.

Pulleys and Belts

Then I had to figure out the pulley situation. I wanted to make sure the supercharger was spinning at the right speed, so I spent some time calculating pulley ratios. I ended up using a combination of off-the-shelf parts and some custom-machined ones. It wasn’t pretty, but it worked. Then came the belt. It took me several tries of different size belts to find one that fit and had the right tension.

Putting It Back Together

With the supercharger in place, I started putting the engine back together. I used new gaskets, new seals, the works. I double-checked everything, torqued all the bolts to the right specs, you know the drill. It was a bit of a pain, but I wanted to make sure it was done right.

Firing It Up

Finally, the moment of truth. I hooked up the fuel lines, the ignition, everything. I turned the key, and it cranked… and cranked… and then, it fired up! It sounded rough at first, but after a bit of tuning, it started to smooth out. And boy, did it sound different! The supercharger whine was music to my ears.

The Results

I haven’t had a chance to really test it out yet, but just from revving it in the garage, I can tell it’s got a lot more pep. It’s definitely a noticeable difference. I’m excited to see what it can do on the road. This project was a lot of work, but it was definitely worth it. There’s just something satisfying about taking an old engine and making it something special.

- Moral of the story: Don’t be afraid to get your hands dirty and try something new. You might surprise yourself with what you can achieve.

I will keep updating on my little project if you are interested.