Man, today was a doozy in the workshop. I decided to tackle something I’ve been putting off for a while – figuring out the whole “pipe or pump instrument” situation for my latest project. Let me tell you, it’s more involved than you’d think.

So, first, I had to wrap my head around what I actually needed. It’s not just about slapping a pump on a pipe and calling it a day. I started by listing out the essentials: the total pressure I’m dealing with, how much fluid needs to move where, and how high I gotta lift the stuff, also the liquid’s features. Sounds simple, right? Nope.

Then, I dug into the different types of pumps. You’ve got your electric motor ones, the steam turbine kind, and even those powered by combustion engines. Choosing the right one depends on what you’re using it for. I spent a good chunk of time reading up on this, and my brain was fried by the end of it.

- Figuring out the head pressure: This took some serious calculations. I had to consider the whole layout of my setup and all the twists and turns the fluid would take.

- Flow rate: This was another headache. I needed to find that sweet spot – not too fast, not too slow.

- Suction lift: Getting the fluid up to the pump without causing a ruckus is an art in itself. I’m still not 100% on this one.

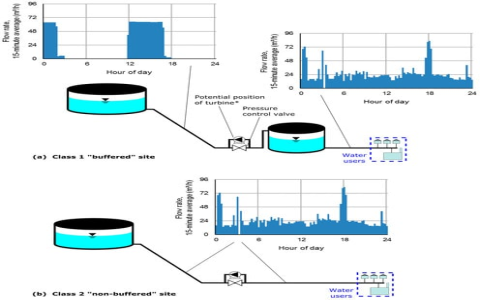

After that, I moved on to the piping. Oh boy, the piping. It’s not just about connecting point A to point B. You’ve got branches, reducers, and all sorts of other doohickeys. I sketched out a basic diagram, trying to make sense of it all.

Breaking Down the PID

This is where things got really interesting. I stumbled upon these things called PIDs – Piping and Instrumentation Diagrams. They’re like the blueprints of this whole operation. I learned that there are standard symbols for everything – tanks, reactors, pumps, you name it.

I found out that there are these ISA S5.1 standards that dictate how to represent instruments on the diagram. Discrete instruments, shared control, computer-based stuff – it’s a whole language on its own. I tried to incorporate some of these symbols into my own crude diagram, and it actually started to look like something a professional might use, kind of.

By the end of the day, I was exhausted, but I felt like I’d actually accomplished something. I still have a long way to go before I have a fully functional system, but at least now I have a better understanding of what I’m dealing with. It’s amazing how much goes into something as seemingly simple as moving liquid from one place to another. Who knew?

Anyway, that’s my progress report for today. I’ll keep chipping away at this project, and hopefully, I’ll have something to show for it soon. It’s a learning process, and I’m definitely learning a lot. Maybe tomorrow will bring more clarity, or maybe it’ll just bring more questions. Either way, I’m in it for the long haul.