Alright, let’s talk about this thing called a dual mass flywheel. I didn’t even know what it was until my trusty old diesel started acting really weird a couple of years back. It wasn’t anything dramatic at first, just this annoying vibration, especially when I was idling at traffic lights. Then came the clunking noises whenever I pressed or released the clutch pedal. Felt really rough, you know?

So, I took it down to my local garage, place I’ve been going to for ages. Left it with them for the day. Later that afternoon, Dave, the owner, gives me a call. He goes, “Mate, got some news. Looks like your dual mass flywheel is on its way out.” I remember just thinking, “My dual… what now?” Sounded complicated and, frankly, expensive.

Digging into the Problem

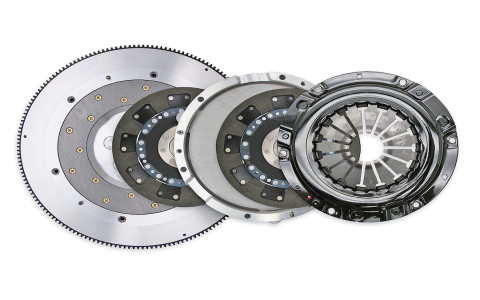

Dave tried explaining it. Said it wasn’t like the old solid flywheels. This thing had springs inside, like two plates connected with springs, designed to soak up the engine vibrations, especially on torquey diesel engines like mine, and make the gear changes smoother. He wasn’t wrong about the smoother part; when it worked, the car was great. But when it failed…

I went home and did a bit of digging online myself, trying to wrap my head around it without getting bogged down in super technical stuff. Found lots of forum posts, mostly people complaining! It seems these things are common now, but they don’t last forever, unlike the old solid lumps of metal. The main points I gathered were:

- Vibration Dampening: Their main job is to stop the engine’s rattle and shake from getting through to the gearbox and the rest of the car. Makes for a quieter, less juddery ride.

- Complexity: Because they have moving parts inside – springs, bearings, stop pins – there’s just more stuff that can wear out or break.

- Cost: And yeah, replacing them is pricey. Often, you have to do the clutch at the same time because getting to the flywheel means taking the whole gearbox out anyway. The parts alone cost a fair bit.

Getting it Sorted

Faced with the facts, I had a decision. The car was getting on a bit, but it had served me well. Selling it with a knackered flywheel wasn’t really an option unless I wanted to give it away. So, I bit the bullet. Told Dave to go ahead and replace it. He ordered the parts – the new DMF and a clutch kit.

It took a couple of days. Getting the gearbox out is apparently a big job on my model. When I went to pick it up, Dave showed me the old flywheel. It was shot. You could wobble the two halves easily, and it made this awful rattling sound. The springs inside were clearly gone.

Driving home, the difference was incredible. Smooth as silk. No more vibrations at idle, no horrible clunks when using the clutch. It felt like a different car, honestly. The whole experience taught me a lot, mostly about how much more complex modern cars are compared to the older ones I used to tinker with myself. These DMFs do a job, making driving more refined, but boy, when they go wrong, your wallet definitely feels it. It was a practical lesson learned the hard way, through actually dealing with the darn thing failing.